- HA-CO

- Linear motion slides

- Linear axes

- Linear axes with toothed belt drive

- ONE (Clean Room System)

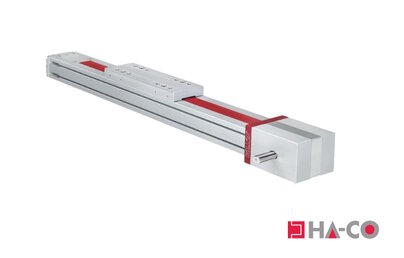

Linear axis One for clean room applications

ONE (Clean Room System)

The One series comprises linear axes with toothed belt drive, which have been specially developed for use in clean rooms.

The system prevents particles from getting into the environment where the linear unit is installed. This has been achieved on the one hand by installing a special seal to close the longitudinal opening of the slider, and on the other hand by using a vacuum pump with 0.8 bar negative pressure, connected to two vacuum lines in the drive head and in the empty head. The vacuum applied to the end heads sucks the particle emission from the inside of the linear unit and carries it away to the air filters. The linear axis components of the Clean Room System are all made of stainless steel or undergo special treatment to ensure low particle emissions. The lubricants used are especially suitable for clean room or vacuum applications.

When the system is used in contaminated environments, the linear units of the Clean Room System can be pressurized up to 0.8 bar to prevent particle ingress.

- Description

- Documents

- Inquiry

Extruded profile: The anodised aluminium extrusions used for the housings of the Rollon ONE series linear units have been designed and manufactured in collaboration with a leading company in this field, in order to achieve the right combination of high mechanical strength and reduced weight. The 6060 alloy used for the anodised aluminium (see below for physical and chemical characteristics) has been extruded with dimensional tolerances that comply with the EN 755-9 standard.

Drive belt: The ONE series is the first linear unit to be driven by a toothed belt that can achieve ISO CLASS 3. We use selected high quality polyurethane timing belts with AT profile, manufactured by an industry leading company.

Carriage: The carriage of ONE Series linear units is made of anodized aluminum. The dimensions vary according to the different types. It consists of three individual parts to allow the protective belt to pass through. Brush seals are inserted in the front and side parts of the carriage to provide additional protection against the penetration of dirt. The threads of the mounting holes are provided with steel inserts.

Covering belt: ONE Series linear units are equipped with a polyurethane belt that protects all mechanical parts inside the profile from dust and foreign bodies. The cover belt is guided by ball bearings located inside the carriage. This allows the cover belt to pass through the carriage with the least friction.