- HA-CO

- Linear motion slides

- Linear axes

- Linear axes with toothed belt drive

- ELM (Plus System)

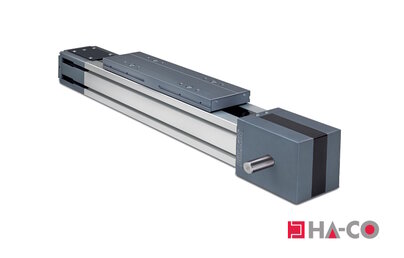

Linear axis ELM (Rollon Plus System) - HA-CO Switzerland

ELM (Plus System)

This extremely versatile main series from Rollon includes fully protected linear axes with toothed belt drive.

The ELM linear units are available in four sizes from 50 to 110 mm. They have a self-supporting profile made of extruded, anodised aluminium. The driving force is transmitted by a steel-reinforced polyurethane toothed belt. The precise movement of the carriage is achieved by linear guides or by an optional roller system.

A polyurethane cover belt protects the belt drive and the LM Guide system from dust, dirt, foreign matter, liquids and other contaminants. This design avoids the weaknesses of other sealing systems, such as steel belts.

The components used for the linear motion, lubricant reservoir, LM blocks and double-lip seals ensure a maintenance-free system. The rollers, bearings and drive shafts used are of an extremely rigid design. The ELM Series LM Guide is particularly suitable for applications in very aggressive operating environments that also require fast work cycles and high repeatability.

The new drive head has been developed to allow great freedom in dimensioning the application and in mounting the gear unit on the ELM series linear drives. With the new drive head it is possible to install the gear unit on the left or right side of the drive using a standard mounting kit.

- Description

- Documents

- Inquiry

Aluminium profile: The self-supporting profiles used in the ELM series of linear units have been designed and constructed in collaboration with a manufacturer in this sector, making it possible to obtain precision anodised extrusions with high mechanical characteristics and high moments of inertia per unit area. The dimensions are tolerated according to the EN 755-9 standard. The material used is anodised aluminium of alloy 6060, and there are also grooves on the outside of the extrusions for quick and easy assembly and for fixing accessories.

Power transmission belt: Steel-reinforced polyurethane timing belts with AT tooth profile are used in the linear units of the ELM series. This type of timing belt has proven to be the most suitable for drive transmission in linear units in terms of permissible drive torques, compactness and noise generation. The combination with zero backlash timing belt pulleys thus enables alternating loads without backlash. The following properties can be achieved by utilising the maximum timing belt width specified by the profile and setting an optimum belt pretension:

- High travel speeds

- Low noise emission

- Low wear and tear

Carriage: The carriage of the linear units of the ELM series is made of anodised aluminium. The dimensions vary according to the different types. It consists of three individual parts to allow the protective belt to pass through. Brush seals are inserted in the front and side parts of the carriage to provide additional protection against the ingress of dirt. The threads of the mounting holes are provided with steel inserts.

Cover belt: The linear units of the ELM series are equipped with a polyurethane belt that protects all mechanical parts inside the profile from dust and foreign bodies. The cover belt is guided by ball bearings located inside the carriage. This allows the cover belt to pass through the carriage with the lowest possible friction.